Types of Fasteners

A Complete Guide to the Different Types of Fasteners

When it comes to construction, engineering, and DIY projects, choosing the right types of fasteners is essential for strength, durability, and safety. Fasteners are hardware devices that mechanically join or affix two or more objects together. They come in various shapes, sizes, and materials, each suited to specific applications.

In this guide, we’ll break down the most common types of fasteners, what they’re used for, and how to select the right one for your project.

1. Screws

Screws are one of the most widely used fasteners in both domestic and industrial applications. They feature a helical thread that cuts into the material as it is driven in, offering excellent grip.

Types of screws include:

Wood Screws – Designed for timber, these have a coarse thread and sharp point.

Machine Screws – Used with nuts or tapped holes in metal and other hard materials.

Self-Tapping Screws – Ideal for metal and plastic; they cut their own thread as they are driven in.

Decking Screws – Corrosion-resistant and specially coated for outdoor use in decking projects.

Coach Screws – Heavy-duty screws with a hex head, suitable for timber and masonry when used with wall plugs.

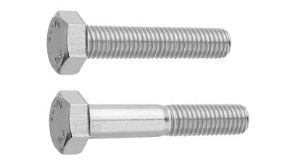

2. Bolts

Bolts differ from screws in that they typically require a nut to secure them in place. They are often used in high-strength applications and can be removed or replaced without damaging the components.

Common types of bolts:

Hex Bolts – Six-sided heads and used with a nut or threaded hole.

Carriage Bolts – Rounded head and square neck to prevent spinning; often used in wood.

Coach Bolts – Similar to carriage bolts but used in structural timber work.

Socket Head Bolts – Designed for use in precision machinery where space is limited.

3. Nuts

Nuts are internally threaded fasteners used in combination with bolts to hold components together. They come in a variety of shapes to suit different needs.

Popular nut types include:

Hex Nuts – Standard six-sided nuts used in a wide range of applications.

Lock Nuts – Designed to resist loosening under vibration.

Wing Nuts – Feature ‘wings’ for easy hand tightening, often used in temporary fixings.

Cap Nuts – Provide a smooth, finished look and protect the bolt thread.

4. Washers

Washers are small, flat discs that are used in conjunction with screws and bolts. They distribute the load, reduce wear, and prevent loosening.

Types of washers:

Flat Washers – Distribute pressure evenly and protect the surface.

Spring Washers – Provide tension to help prevent fasteners from loosening.

Fender Washers – Larger diameter for more surface coverage, often used in sheet metal work.

5. Nails

While technically not threaded fasteners, nails are commonly used in woodworking and construction. They are driven into materials using a hammer or nail gun.

Types of nails:

Common Nails – General-purpose nails with a thick shank.

Finishing Nails – Smaller heads, ideal for a cleaner finish.

Clout Nails – Short with large heads, often used in roofing and fencing.

Ring Shank Nails – Provide better holding power in wood due to their ridged shank.

6. Anchors

Anchors are used to attach fasteners to materials that would otherwise not support them, such as drywall, brick, or concrete.

Key anchor types:

Wall Plugs – Expand in the hole to hold screws in place in masonry.

Shield Anchors – Heavy-duty anchors ideal for concrete and stone.

Toggle Bolts – Used for hollow walls; expand behind the wall for secure fixing.

Chemical Anchors – Use resin to create a strong bond in masonry or concrete.

7. Rivets

Rivets are permanent mechanical fasteners used to join two or more materials, typically metal, by passing a shaft through a hole and deforming one end to hold it in place. Unlike screws or bolts, rivets do not rely on threads, making them ideal for applications where vibration resistance and strength are critical.

Common types of rivets include:

Pop Rivets (Blind Rivets) – Designed for use when only one side of the material is accessible. Installed using a rivet gun, they expand to secure materials tightly.

Solid Rivets – One of the oldest types, often used in structural applications like bridges and aircraft. They require both sides of the material to be accessible during installation.

Tubular Rivets – Feature a hollow shaft and are often used in leather goods, clothing, or light metalwork.

Drive Rivets – Installed by driving a pin into the rivet body, expanding it to hold materials together. Often used in automotive and electrical applications.

Rivets are particularly useful in applications where welding or threaded fasteners are impractical. They offer a clean, tamper-proof finish and excellent long-term performance under stress and movement.

8. Threaded Rods

Threaded rods, also known as stud bolts or all-thread, are long, straight rods that are fully or partially threaded along their length. These versatile fasteners are used in a wide range of construction, engineering, and maintenance applications where a secure and adjustable fixing is required.

Key features of threaded rods:

Fully Threaded Rods – Provide continuous thread, making them suitable for tensioning and anchoring over long spans.

Partially Threaded Rods – Offer a combination of grip strength and flexibility, commonly used where shear loads are present.

Available in a range of materials – Including mild steel, stainless steel, and zinc-plated options, depending on the environment and load requirements.

Threaded rods are often used with nuts and washers to fix heavy items, suspend pipework or ducting, and anchor structural components. Their strength, adaptability, and ease of installation make them an essential fastener in both industrial and commercial projects.

Choosing the Right Type of Fastener

The right fastener depends on the materials you're working with, the load it needs to bear, and whether the joint will be permanent or temporary. When selecting, consider:

Material – Stainless steel for corrosion resistance, zinc-plated for indoor use.

Thread Type – Coarse for wood, fine for metal.

Head Style – Hex, countersunk, or pan head depending on access and aesthetics.

Environmental Factors – Outdoor applications require weather-resistant fasteners.

Understanding the different types of fasteners available can make all the difference in the success and longevity of your project. Whether you're building a deck, assembling machinery, or tackling a home improvement task, having the right fastener ensures everything stays securely in place.

Explore our full range of fasteners at Central Fasteners to find the perfect fit for your job.